Solder Preforms

Request a sampleIndium Corporation is a world-leader in the design and manufacture of high-quality solder preforms, used in a variety of applications that require precise amounts of solder or flux, such as pin-in-paste, void reduction or uniform bondline . They are and available in various shapes, sizes (including ribbons and spheres) and alloy, with the possibilty to have flux coating or reinforcement.

Have a question? Get in touch

|

|

|

Solder Fortification® Preforms

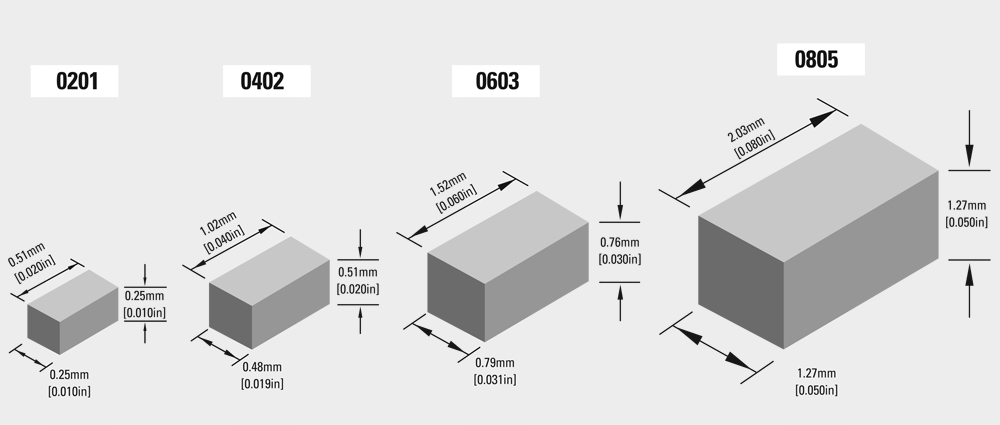

Obtaining the precise amount of solder to ensure a stronger solder joint is critical in electronics manufacturing. However, miniaturization trends, such as the reduction of stencil thickness and more tightly fitted components, make this increasingly difficult. Solder Fortification® Preforms can provide the solution for these challenging issues.

Solder Fortification® Preforms are rectangular shaped pieces of alloyed metal that do not contain any flux. The preform is added to a deposit of solder paste using standard pick and place equipment. Since the alloy for both the preform and the solder paste are the same, the preform will reflow at the same temperature as the solder paste, with the solder paste providing the necessary flux. The preform increases the volume of solder above what could be achieved with just solder paste, especially for applications using stencils with a pitch of 0.3mm or less.

Flux-Coated Preforms

Flux-Coated Preforms eliminate the costly production step of separate fluxing and increase throughput yields. Flux Coatings for Preforms are available in no-clean and rosin-based chemistries with a variety of activity levels to suit your substrate metallizations.

- Eliminates the need for manual fluxing

- Eliminates excessive flux residue

- Increases productivity

- Applies flux precisely where it is needed

- Applies a uniform amount every time

InFORMS® Reinforced Matrixed Solder Composite

InFORMS® are reinforced matrixed solder composites. This process produces a reinforced solder fabrication with improved strength and creates a more consistent bondline thickness. A uniform bondline maximizes the thermal and mechanical reliability in the solder joint, therefore, producing solder joints that are higher in reliability.

During the soldering process, the copper does not melt, ensuring that the bondline is maintained across the entire solder joint. This results in:

- Improved mechanical and thermal reliability

- Uniform bondline thickness

- Low-voiding performance