In-Mold (IME)

Request a sampleThe Next Generation Human Machine Interface. Meet the perfect union of form and function. One that combines an innovative, more stretchable material with dramatic advancements in electronic ink to give interface designers new creative freedom, without any compromise in meeting functional switching needs. And because these new electronic inks work with existing in-mold decorative processes, there’s no need for costly re-tooling.

Have a question? Get in touch

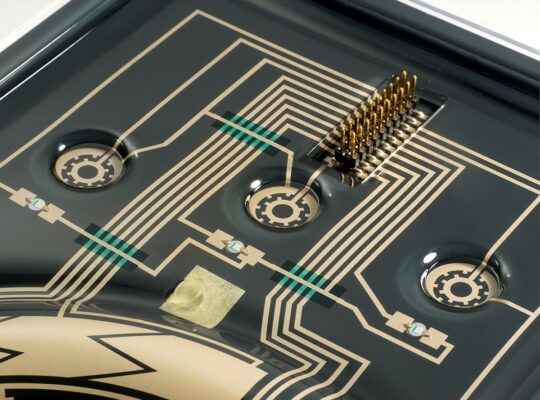

In-Mold Electronics funcional inks system

Micromax™ suite of materials developed for In Mold Electronic applications including formable silver, carbon, transparent conductor and formable dielectric, encapsulant and led-attach adhesive.

Features and Benefits:

More than 70% lighter

Buttons and wires account for most of the weight in conventional switches. Our In-Mold Electronic Technology eliminates them both.

Up to 30% less cost

With fewer parts and manufacturing steps, In-Mold Electronic Technology makes production simpler and more efficient than even before.

Part assembly time cut by 40%

Assembly is a single-connection, “snap-on” process, significantly reducing assembly time while increasing reliability and enhancing ease of service.

New design freedom:

Your ideas are no longer constrained by the need to conform to bulky circuitry. Capacitive LED switches can now be arrayed anywhere, in virtually any shape.

Applications:

Appliances, Automotive, Aerospace, Consumer Electronics and many more.