Electroactive powder and inks

Request a samplePiezotech®, an Arkema Group company, proposes a unique range of electroactive polymers. With the help of R&D labs specialised in electroactive materials and client partners all around the world, Piezotech® is at origin of key achievements in the field of organic electronics and printed electronics.

Have a question? Get in touch

P(VDF-TrFE) copolymers powder

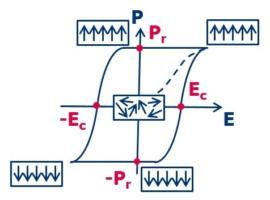

PIEZOTECH® FC COPOLYMERS are an excellent choice for sensors, energy harvesting, actuators, speakers and memories. They are very stable (resistance to moisture, and to temperatures up to 120 °C) and exhibit high sensitivity over a wide range of pressure (mPa to GPa) and frequency (mHz to GHz). They exhibit excellent mechanical properties (high elastic modulus and flexibility) and transparency.

Sensors fabricated from PIEZOTECH® FC copolymers enable the development of unique applications with detection through touch, deformation, ultrasounds, heat, impact, acoustic waves. Thanks to the piezoelectric effect, sensors do not require an external power source, strain is rapidly induced on these materials when exposed to an electric field. Actuator performance is enabled by their high energy density response, even at low electric fields (< 50 V.μm-1).

| Product name | Typical TrFE content (mol%) | Curie Temperature (°C) | Typical remnant polarization at 150 V/µm (mC/m²) | Typical d33 (pC/N) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Piezotech® FC20 |

20 |

136 |

85 |

-24 to -30 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Piezotech® FC25 |

25 |

115 |

70 |

-24 to -30 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Piezotech® FC30 |

30 |

100 |

65 |

-18 to -22 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Piezotech® FC45 |

45 |

60 |

45 |

-18 to -22 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Values given as indicative, not specifications. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

P(VDF-TrFE-CTFE) or P(VDF-TrFE-CFE) Terpolymer Powders

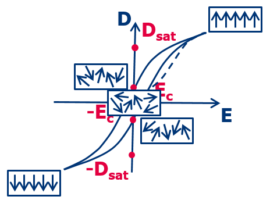

P(VDF-TrFE-CTFE) or P(VDF-TrFE-CFE) are unique relaxor ferroelectric polymers that exhibit high electrostrictive strain and high dielectric constants.

- High deformation (directly proportional to the applied electric field squared, E²)

- High elastic energy

- High stress

| Product Name | Termonomer | Typical termonomer content (mol%) | Typical melting point (°C) | Typical relative dielectric constant (1 kHz) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Piezotech® RT-TS |

CTFE |

Standard composition, please contact us |

122 |

40 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Piezotech® RT-FS |

CFE |

Standard composition, please contact us |

127 |

55 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Values given as indicative, not specifications. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

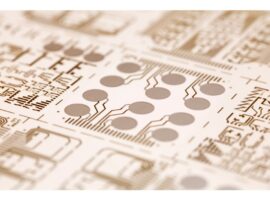

Piezotech® FC Inks and RT inks

Solvents and concentrations have been optimized to allow for the use of standard printing conditions. 3 standard formulations (ink L, ink P, ink H) adapted to conventional techniques are available.

Standard Piezotech® FC Inks are formulated with Piezotech® FC20 polymer powder.

Standard Piezotech® RT Inks are formulated with Piezotech® RT-TS polymer powder.

| Grade | Technology | Viscosity (mPa.s at 32°C) | Thickness range (µm) | Indicative dry content (wt%) | FC Inks dts | RT Inks dts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Ink L |

Spin-coating |

<1000 |

0.1-2 |

7 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ink H |

Spin-coating |

1500-3000 |

Spin coat: 0.5-2 |

20 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ink P |

Screen-printing |

15000-20000 |

1-10 |

17.5 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Values given as indicative, not specifications. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|